Company News | 2024-12-26

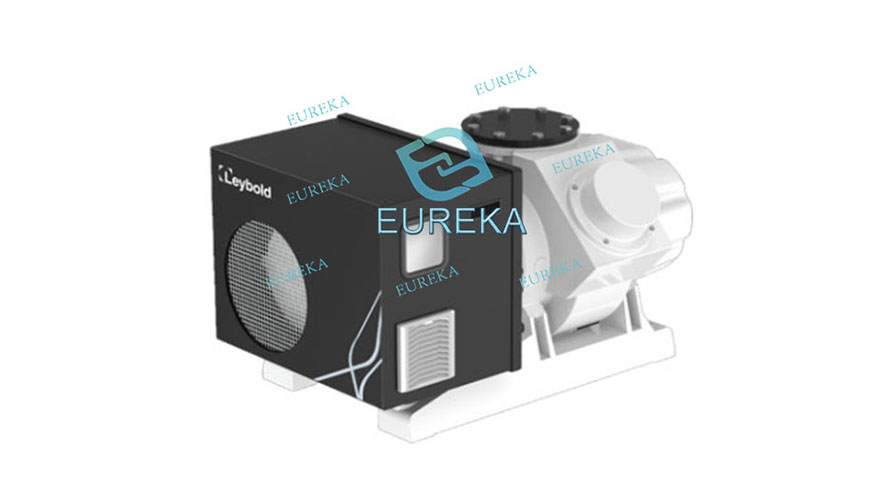

WELCH CRV pro4 vacuum pump repair-Shenzhen EUREKA Technology Co., Ltd

I. Basic information of equipment

The vacuum pump is a university laboratory equipment, since 2022 since the use of a replacement of the pump oil, the rest did not make any maintenance

Failure 1: vacuum pump rattling

Failure 2: vacuum pump oil leakage

Failure 3: the vacuum pump temperature rises abnormally

Ⅱ. Maintenance inspection

The maintenance personnel disassembled the equipment according to the standard disassembly process of Weiyi CRVpro4 vacuum pump, focusing on checking the following key components:

1. Internal wear of the pump body: The inspection found that there are a certain degree of wear marks on the inner wall of the pump body and the surface of the rotor.

2. Condition of seals: Check the seals everywhere, such as shaft seals, O-rings, etc., and find that some seals have aged, deformed, and lost their original sealing effect. Especially the shaft seal, there is obvious wear and aging, which will not only cause leakage and affect the vacuum degree, but also may cause lubricating oil to seep out.

3. Lubricating oil status: Observe the lubricating oil in the vacuum pump and find that its color has become dark and turbid, and there is slight gumming in the pump. This indicates that the lubricating oil has been contaminated and its lubrication performance has dropped significantly, and it cannot effectively control the movement. The components are lubricated and dissipated, which increases the wear between components and may also be a factor causing increased operating noise.

Maintenance measures:

Update seals

Repair of pump body and rotor

Pump body cleaning and assembly

Ⅲ. Maintenance test

After assembly, technicians from Urico Technology Co., Ltd. tested the Weiyi CRVPRO4 vacuum pump.

After startup, the operating sound became significantly smoother than before maintenance;

No oil leakage occurred after running for a period of time, and the pump temperature was normal;

Measured by a special vacuum gauge, the vacuum degree is stable and good.

Ⅳ. Suggestions

Regular lubrication: According to the period specified in the equipment maintenance manual, perform appropriate lubrication operations on key moving parts such as bearings and rotors of the vacuum pump to ensure good operation between components and reduce wear.

Cleaning and maintenance: Regularly clean dust, oil and other impurities on the surface and inside of the pump body, keep the equipment clean, and prevent impurities from entering the pump cavity and causing damage to mechanical components.

Professional vacuum pump repair, new vacuum pump accessories:Shenzhen EUREKA Technology Co., Ltd

www.eurekasz.com