Company News | 2024-01-11

How to start repairing Aifake oil-sealed rotary vane pump?-EUREKA

Aifake vacuum pump is a common equipment commonly used in industrial production. Long-term operation of Aifake vacuum pump will cause the wear of the iron parts of the vacuum pump and the aging of the seals, resulting in insufficient vacuum, oil leakage, and high temperature in the Edward vacuum pump. If abnormal noise occurs, the vacuum pump needs to be repaired.

1. Clean vacuum pump

Before disassembling the vacuum pump, it must be cleaned first. First, the surface of the vacuum pump needs to be cleaned. You can use a special alcohol-based cleaning agent to wipe and disinfect the surface of the vacuum pump. After cleaning, you also need to check whether there are any problems with pipelines, valves and accessories. If damage or blockage occurs, it needs to be repaired or replaced in time.

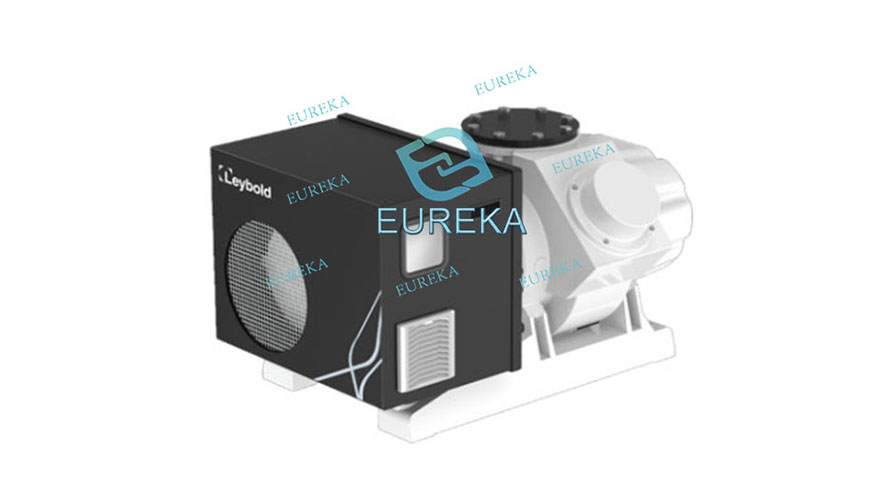

picture

2. Replace parts

If an abnormality occurs when using the vacuum pump, it is likely to be caused by damaged parts. Through observation and testing, you can determine which parts need to be replaced. Common parts that need to be replaced include bearings, seals, mechanical seals, motors, etc. When replacing, you need to disassemble it according to the instructions first, and use special tools to ensure that other parts will not be damaged during the replacement process.

3. Check the pipeline

When the pump is working normally, check whether the vacuum pump generates high temperature. One of the reasons why the vacuum pump generates high temperature is due to blockage in the pipeline. Therefore, during use, you need to pay attention to check whether there is blockage, air leakage, etc. in the pipeline.

If a problem occurs, it needs to be dealt with promptly. First, you can try cleaning the pipes with compressed air. Then, check whether each connecting part is tight to avoid air leakage. In addition, the filter needs to be replaced or cleaned regularly to ensure that the pipeline is unobstructed.

The above is the repair and maintenance of vacuum pump failures by EUREKA. I hope it will be of great help to you in dealing with vacuum pump failure repairs!