Industry News | 2024-10-22

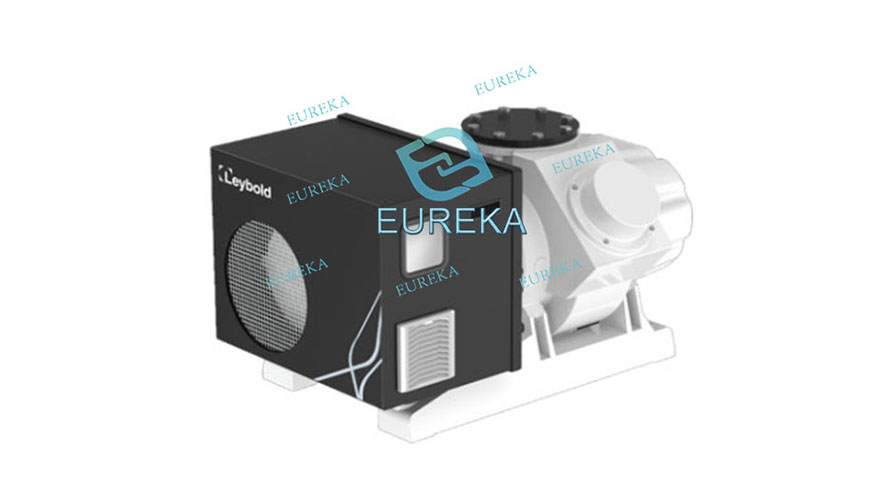

Famous Vacuum Equipment Manufacturer-Leybold Vacuum Pumps

Leybold vacuum pumps are one of the world's leading suppliers of vacuum equipment. Here are some introductions about Leybold vacuum pumps:

1. Product structure and series:

- Single-stage oil-sealed rotary vane pump (Sogevac series): this is an important series of Leybold vacuum pumps. The pump itself is equipped with an anti-oil return valve, gas ballast valve (optional), outlet filter, oil return line and oil cooling circuit. It is driven by a direct coupled flange motor. Its features include compact structure, small size and space saving; it can be used with various accessories to meet different application requirements.

- Two-stage oil-sealed rotary vane pumps (Trivac series): built-in oil pump for forced lubrication of the pump chamber, can be continuously operated under atmospheric inlet pressure; built-in automatic anti-return valve, when the pump stops the air inlet can be automatically shut off to prevent the return of oil; the air inlet and air exhaust port can be mounted in two ways: horizontally or vertically. There are also a number of vacuum pumps in this series for special applications, such as those dedicated to automotive brake fluid injection, explosion-proof pumps for specific refrigerant charging in the refrigeration industry, and corrosion-resistant pumps for the semiconductor industry.

- Roots vacuum pumps (Ruvac series): Two symmetrically arranged impellers in the pump housing rotate in opposite directions and are suitable for applications requiring high pumping speeds. Used in conjunction with a pre-stage pump, it improves the pumping efficiency of the vacuum system.

- Scroll vacuum pumps (Scrollvac series): Operating on the principle of a scroll compressor, each pump integrates two Archimedean helical screws, which reduce the volume of the grooves and compress the gases from the outside in to create a vacuum, providing a flexible, stable and simple vacuum solution for a wide range of applications.

- Diaphragm pumps (Divac series): For environments such as laboratories where cleanliness is critical. For example, the DivacL two-stage diaphragm pumps are suitable for almost all applications in chemical laboratories, with special corrosion- and solvent-resistant materials for the parts of the pump that come into contact with the pumped medium.

2. Technical features:

- Strong ability to remove water vapor: the ability to effectively pump out water vapor from gases, which is very important for applications with high vacuum environment requirements and the presence of water vapor.

- Environmental protection and oil saving: the outlet oil mist filter is the standard configuration, and the vacuum pump oil can be recycled without oil smoke, which is both clean and environmental protection, and also saves the cost of oil.

- Continuous working: it can work continuously under the condition that the inlet pressure is atmospheric pressure, with high working stability and reliability.

- Good pumping speed performance: it can maintain high pumping speed under low pressure, and can quickly and effectively establish and maintain the vacuum environment.

- Low noise and vibration: low noise and vibration during operation reduces the impact on the working environment and also helps to extend the service life of the equipment.

3. Areas of application: Leybold vacuum pumps are widely used in a number of industries:

- Semiconductor industry: In the semiconductor production process, vacuum equipment plays an extremely important role, Leybold vacuum pumps can meet the semiconductor industry's strict requirements for the vacuum environment, such as chip manufacturing, semiconductor packaging and other links.

- Analytical instrument industry: analytical instruments need to operate under vacuum conditions, Leybold vacuum pumps have many types of products, which can be applied to laboratory research and development as well as simple desktop operation, providing a stable vacuum environment for analytical instruments.

- Industrial applications: including food processing and packaging, vacuum coating, heat treatment and metallurgy, production of environmentally friendly refrigerators and air conditioners, production of high-purity and high-strength metals, manufacture of light bulbs and color picture tubes, and manufacture of flat panel displays.

- Scientific research: to provide a reliable vacuum environment for scientific research experiments and support various scientific research projects.

4. Brand advantage: Leybold has a long history and rich experience, and has been committed to the research and development of vacuum technology. With factories in many countries around the world, it produces reliable products with excellent quality and performance, and constantly introduces new products to meet market demands. The company strictly controls the product development and production process to ensure the quality and stability of the products.