Company News | 2024-01-15

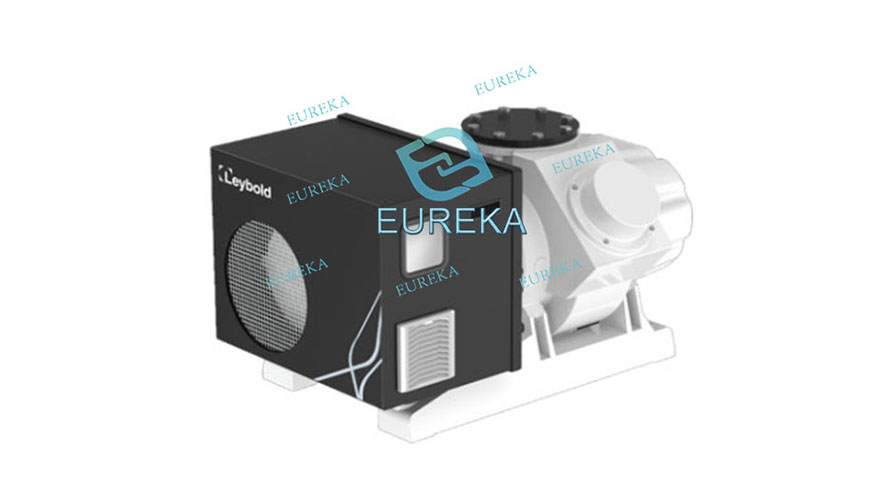

Where to start repairing Leybold oil-sealed rotary vane pumps?-EUREKA

Leybold vacuum pumps are widely used in various industrial fields, including chemistry, pharmaceuticals, electronics, semiconductors,

etc. When the vacuum pump is used for too long or is used improperly, it will cause damage to the vacuum pump. Common problems

include insufficient vacuum, oil leakage, and abnormal noise in the vacuum pump. So how to repair it?

What are the reasons why the vacuum pump cannot pump air:

1. The sealing gasket is aging and the sealing performance is deteriorated.

2. Insufficient vacuum degree

3. The shaft seal is hardened, affecting the sealing effect. This affects the slow pumping of the vacuum pump.

Solution to slow pumping of vacuum pump:

1. Replace the sealing gasket, replace the vacuum pump oil, and replace the oil seal.

2. Precautions for daily maintenance of the vacuum pump: Under normal circumstances, the vacuum pump should be inspected after

2,000 hours of operation. Check the aging degree of the rubber seal, check whether the exhaust valve plate is cracked, and clean the

dirt deposited on the valve plate and exhaust valve seat. .

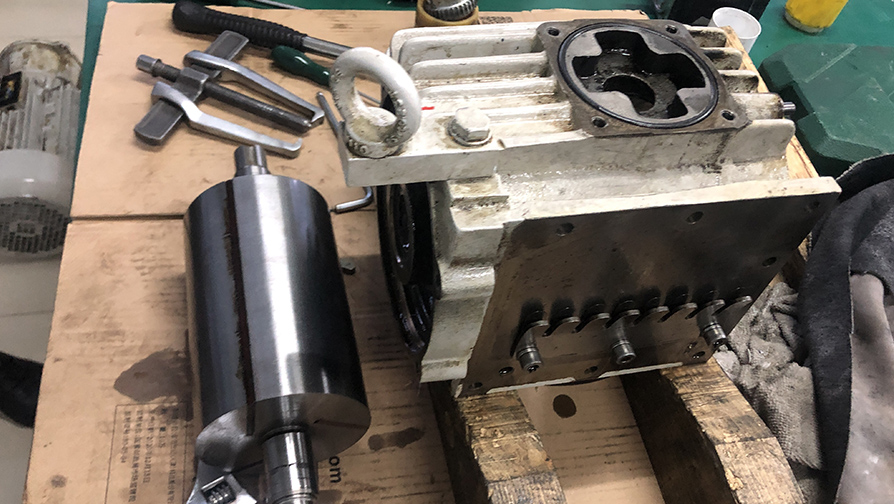

Clean the parts in the entire vacuum pump cavity, such as rotors, vanes, springs, etc. Generally use gasoline to clean and dry. After cleaning

the rubber parts, wipe them dry with a dry cloth. If possible, clean the pipes as well to ensure smooth flow.

Abnormalities in the vacuum pump need to be dealt with promptly, and professional maintenance personnel are required to repair them if necessary. The above is EUREKA Vacuum’s experience in vacuum pump failures and solutions. It is for reference only. I hope it can be helpful to you!