Company News | 2024-01-02

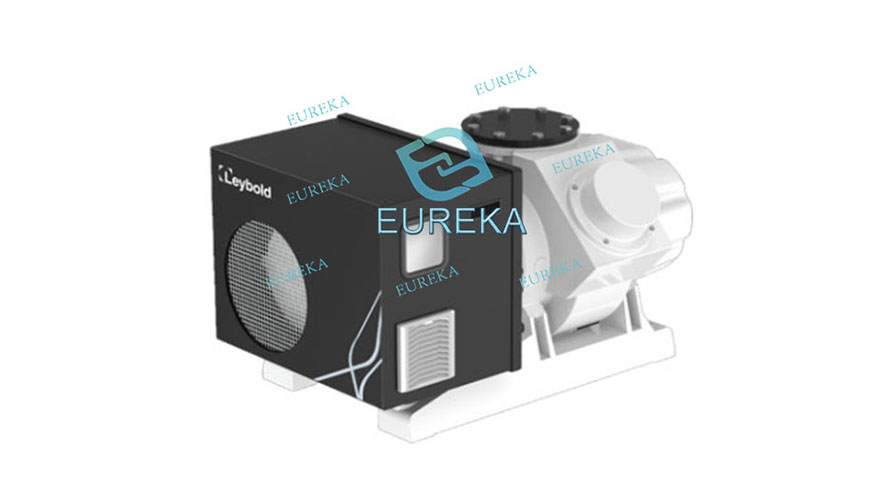

Leybold SV630B vacuum pump repair (SV630B end cover)-EURUKA

Leybold SV630B has a pumping capacity of 640m3/h at a frequency of 50Hz. It is a single-stage oil-sealed rotary vane pump with a considerable pumping capacity. It is mainly used in the coating industry. The pump itself is equipped with an anti-backflow valve, gas ballast, exhaust filter, oil return pipeline, oil cooling circuit and thermal protection switch. The pump is driven by a fixed base electric motor via four V-belts.

There are three rotor vanes installed eccentrically in the pump body, which divide the pump chamber into several chambers. of each cavity

The volume changes periodically as the rotor rotates. As the rotor rotates, the volume of the air inlet part of the pump chamber expands, sucking gas through the air inlet. The gas enters the pump chamber through the sewage screen and the opened anti-oil return valve. As the rotor rotates further, the vanes partially separate the pump chamber from the air inlet. Then the volume of this part of the pump chamber decreases and the gas is compressed. The gas is discharged from the pump chamber through the exhaust valve at a pressure slightly higher than atmospheric pressure.

Oil is injected into the pump chamber to seal, lubricate and cool. The oil entrained by the compressed gas is initially captured in the tank due to deflection, and then thoroughly filtered in the eight exhaust filters.

The oil content in the exhaust gas drops below visible levels (capture rate is greater than 99%). The oil trapped in the exhaust filter returns to the pump chamber through the oil return line. In order to prevent gas at atmospheric pressure from entering the air inlet from the oil tank, the oil return line is controlled by a float valve. Oil circulation is maintained by the pressure difference that exists between the oil tank (pressure above or equal to atmospheric pressure) and the air inlet of the pump (pressure below atmospheric pressure). The built-in anti-oil return valve maintains vacuum in the vacuum chamber and prevents oil return. However, the anti-backflow valve is not a safety valve like a valve.

The thermal protection switch serves as an additional fault protection device and works by measuring the exhaust temperature of the pump body.

This is a single-stage pump with quite good performance, but sometimes the pump is not parked level enough during installation, causing the pump to tilt. This may cause friction between the rotor and the chamber end cover, eventually forming a groove, and finally causing the pump to tilt. It gets stuck during operation, causing damage to the motor, etc. Therefore, it is necessary to check the operation of the machine from time to time. If abnormal noise occurs, please repair it in time. If the end cover has deep grooves due to friction, please replace it in time.

Please contact us---EUREKA will solve your needs!