Company News | 2024-01-15

What black technologies are used to make disposable plastic plates?--EUREKA

On the busy streets, roadside vendors can be seen everywhere shouting, and constantly using disposable bowls to distribute food to

waiting diners. After waiting for the diners to take the food, they do not forget to ask each other to come back next time. These are all

normal things. Perhaps few people would think about how the disposable plastic tableware we usually see is produced. Is this mixed

with a little "black technology"?

In fact, these disposable tableware are mainly produced through thermoforming. Thermoforming is a two-step process. It begins by

heating plastic pellets, usually polyethylene, to form extruded plastic sheets of the desired thickness. Then, when the air between the

mold and the sheet is evacuated, in layman's terms, heated plastic particles are added to the mold. Because polyethylene has thermoplasticity,

the plastic particles can change it at will after heating. shape. After adding hot plastic to the mold, use a vacuum pump to evacuate the air

in the mold, allowing the plastic to stick tightly to the mold, and finally wait for cooling to form. We ended up with the disposable plastic cutlery

we see now. Thermoformed plastic pallets are typically very lightweight and durable. Double-panel thermoformed pallets are hollow and tend to

retain water if punctured and exposed to rain.

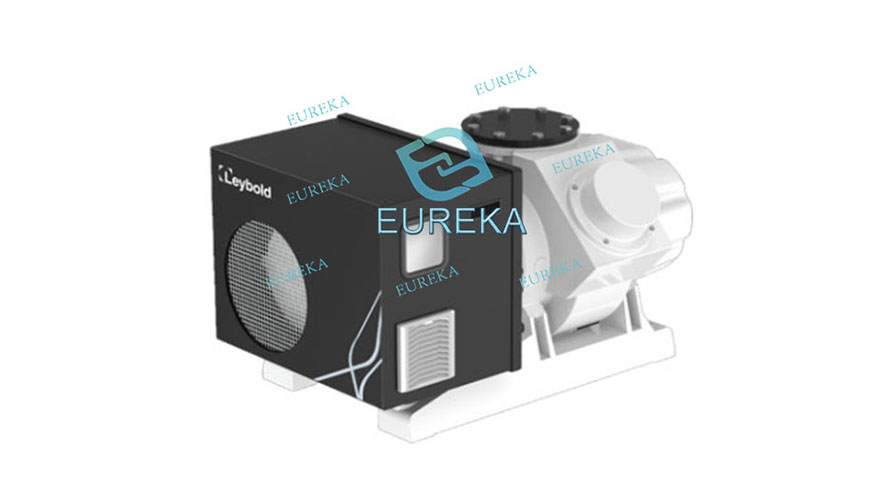

So what is the "black technology"? Of course, it uses a vacuum pump to extract the air from the mold to achieve the purpose of product

molding. This method is simple, fast, low-cost, and fast in production. How to choose a suitable vacuum pump and what pumping capacity

to use? Then you can consult us at EUREKA Vacuum. We can provide you with advice on vacuum systems and help you solve the problems

you encounter!